Which Steel Gauge Should You Choose for Metal Roofing and Siding?

Choosing the right steel gauge for your metal roofing or siding project is more than just a technical detail, it directly impacts your building's performance, durability, and long-term value. Whether you're sourcing painted metal coils or finished panels, understanding steel gauges helps you make informed decisions that align with both project demands and budget.

In this article, we’ll walk you through the essentials of steel gauge selection using a metal panel gauge chart, break down the difference between 24 vs 26-gauge steel, and offer tips for selecting the best roof panel thickness for your application.

Understanding Steel Gauges: Why Thickness Matters

Steel gauge refers to the thickness of the sheet metal. In the U.S., the higher the gauge number, the thinner the metal. For example, 29-gauge steel is thinner than 26 gauge.

Common gauges used for metal building panels include:

- 22 gauge – Thick and durable; often used in industrial or heavy-duty applications.

- 24 gauge – Strong and resilient; popular for standing seam roofing and commercial buildings.

- 26 gauge – A versatile and economical choice; ideal for residential roofing and siding.

- 29 gauge – Lightweight and cost-effective; generally used in agricultural or non-structural applications.

For a full reference, consult this metals gauge chart.

24 vs 26 Gauge Steel: Which One Should You Use?

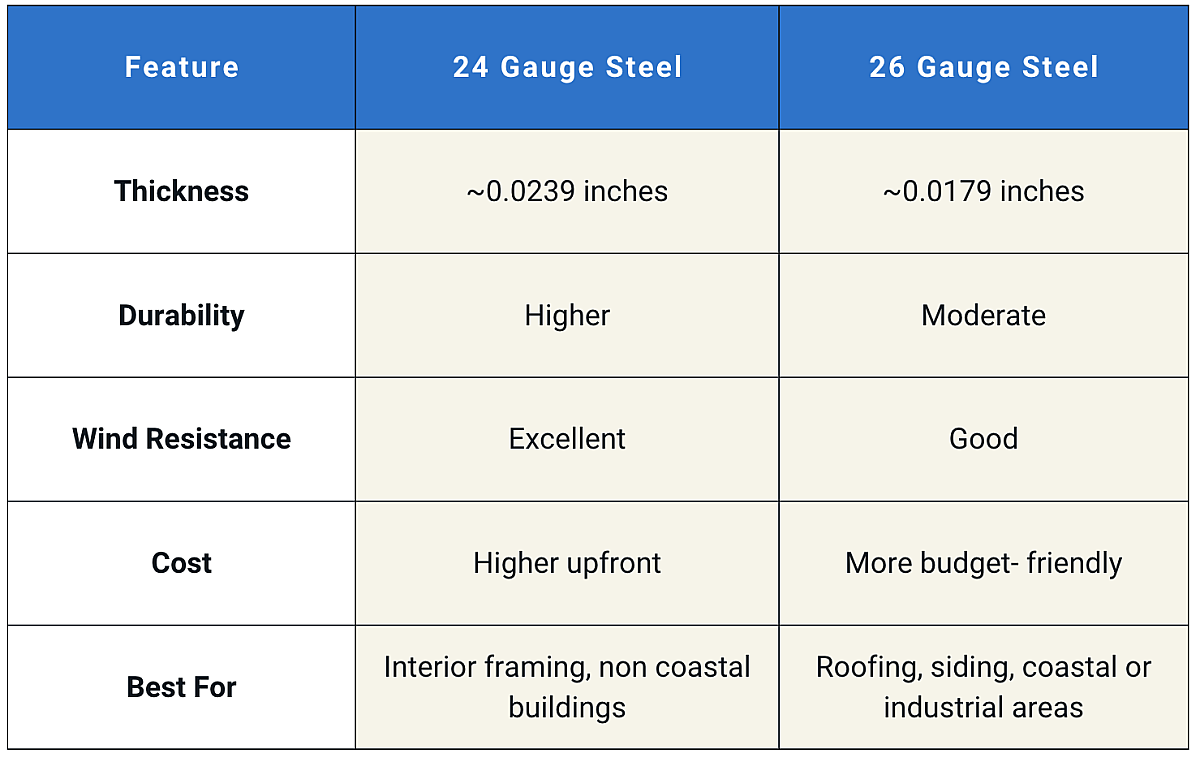

The 24 vs 26 gauge steel debate comes up frequently when selecting roofing or siding materials. Here’s a quick comparison to help guide your decision:

If you’re building in a region prone to extreme weather or require additional structural strength, 24 gauge is worth the investment. On the other hand, 26 gauge is a reliable option for typical residential projects with fewer environmental demands.

How to Choose the Right Gauge: Roof Panel Thickness Guide

When choosing your steel gauge, consider these factors:

1. Location and Climate

- Coastal and high-wind areas may benefit from heavier gauges (22–24).

- Milder climates can often utilize 26–29 gauge panels.

2. Building Use

- Industrial or commercial buildings should prioritize strength and longevity.

- Agricultural buildings or garages may use lighter gauges to reduce cost.

3. Painted Metal Coils and Coatings

Heavier gauges typically support thicker, more durable coatings, making them ideal for painted metal coils used in long-lasting architectural applications. Always ensure your panels meet ASTM standards for structural and paint performance.

4. Span and Support Structure

Wider panel spans require thicker gauges to prevent oil canning and sagging. You can learn more about defects such as these from this guide by the National Coil Coating Association. Consult with your panel manufacturer or supplier for specific load and span tables.

Reliable Supply and Support

At Mill Steel Company, we supply high-quality painted metal coils and flat-rolled steel products in a wide range of gauges and finishes. Our knowledgeable team can help you match your project to the right material to balance performance, aesthetics, and budget.

We’re more than just a supplier – we’re a partner committed to helping you succeed.