Understanding Metal Gauge: A Buyer’s Guide for Steel, Stainless, and Aluminum

When purchasing metal for a construction or manufacturing project, one of the most important and often confusing factors is gauge. This term, used to describe metal thickness, can vary widely depending on the material. In this article, we’ll break down what gauge means, how it differs by metal type, and offer key tips to help you choose the right gauge for your application.

What Is Gauge in the Metal Industry?

Gauge refers to the thickness of a sheet metal product, but it isn’t measured in inches or millimeters. Instead, it's represented by a numerical value—where a lower number means a thicker sheet. For example, 10-gauge steel is thicker than 20-gauge steel.

This non-linear and non-standardized measurement system was established in the 19th century and originally based on the number of times a metal sheet had to pass through rollers to achieve a specific thickness. Over time, it evolved separately across different metal types, leading to the variations we see today.

Why Gauge Varies by Metal Type

A common point of confusion arises when comparing gauge across steel, stainless steel, and aluminum. Although the same gauge number may be used, the actual thickness (in inches or mm) is different for each metal.

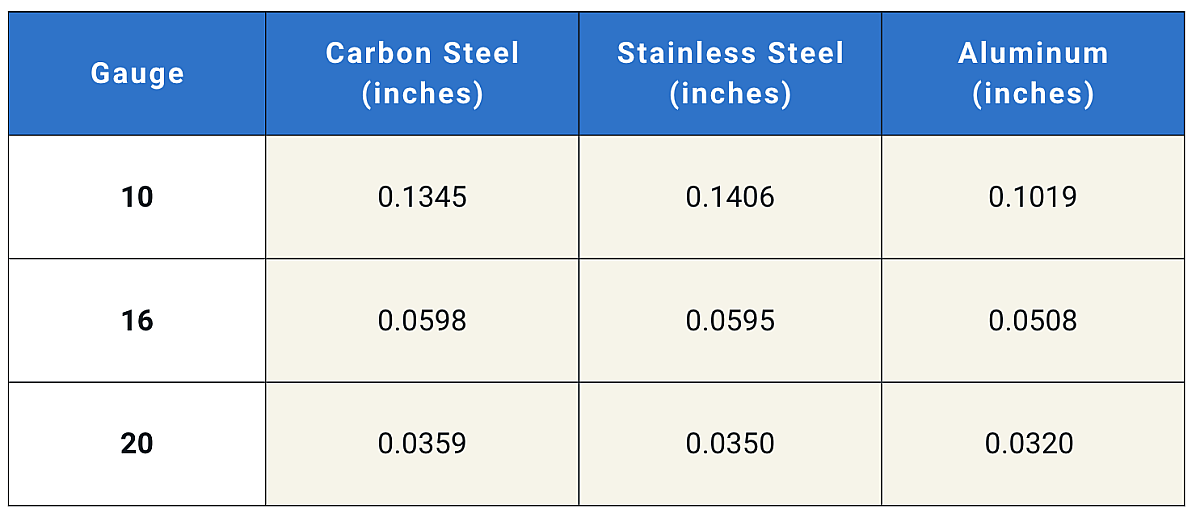

Here’s a quick comparison:

These differences are critical when you're trying to meet strength requirements or design tolerances.

For a detailed reference, review Engineering Toolbox’s sheet metal gauge tables.

Tips for Selecting the Right Gauge

Choosing the correct metal gauge depends on several factors. Here’s what metal buyers in the manufacturing and construction sectors should consider:

1. Know Your Application Requirements

- Structural parts typically need a thicker gauge for strength and load-bearing capacity.

- Aesthetic elements, like fascia panels or trims, can use thinner gauges.

- Environmental exposure (e.g., coastal environments) may require thicker gauge stainless steel, painted steel, or aluminum for corrosion resistance.

2. Don’t Assume All Gauges Are the Same

As mentioned, a 16-gauge aluminum sheet is significantly thinner than a 16-gauge steel sheet. Always confirm the actual thickness (in inches or mm) when specifying materials.

3. Factor in Manufacturing Methods

Processes like bending, stamping, or welding can impact the integrity of thinner gauge metals. Discuss processing needs with your metal supplier to ensure compatibility.

4. Consider Weight and Cost

Thicker gauges weigh more and cost more – not just in raw materials but also in freight. Optimize your material selection based on performance vs. cost trade-offs.

5. Consult with Experts

When in doubt, partner with a trusted metal supplier like Mill Steel. Our knowledgeable sales and technical teams can help you specify the right gauge and metal type for your project’s unique demands.

Why Gauge Selection Matters

Making the right choice in metal gauge affects not just the performance but also the longevity, safety, and budget of your project. Whether you're sourcing steel for building frames, stainless for food processing equipment, or aluminum for transportation components, getting the gauge right from the start pays off long-term.

Work with a Trusted Partner

Mill Steel is a supply chain partner you can trust. With an expansive inventory of steel, stainless, and aluminum products and a team that understands industry-specific needs, we make material sourcing easier—and smarter.

Learn more about our product offerings and markets served.