The Value of 409 Stainless Steel in Budget-Conscious Projects

When durability and heat resistance are required—but the budget is tight—409 stainless steel offers the ideal balance of performance and affordability. Known for its excellent oxidation resistance and formability, 409 is a cost-effective choice for a wide range of applications, especially in the automotive, HVAC, and industrial sectors.

At Mill Steel Company, we supply 409 stainless steel to manufacturers across North America who demand quality, consistency, and rapid delivery. Whether you’re fabricating exhaust components, heat shields, or agricultural equipment, our inventory and processing expertise help you stay competitive without compromising on material integrity.

What Is 409 Stainless Steel?

409 stainless steel is a ferritic, heat-resistant alloy primarily composed of iron, chromium (around 11%), and trace amounts of other elements. It’s designed to offer oxidation and corrosion resistance in mildly corrosive environments, especially at elevated temperatures.

It’s commonly used in:

- Automotive exhaust systems and mufflers

- Heat exchangers and HVAC components

- Agricultural and off-road equipment

- Commercial kitchen or food service structures where full corrosion resistance isn't required

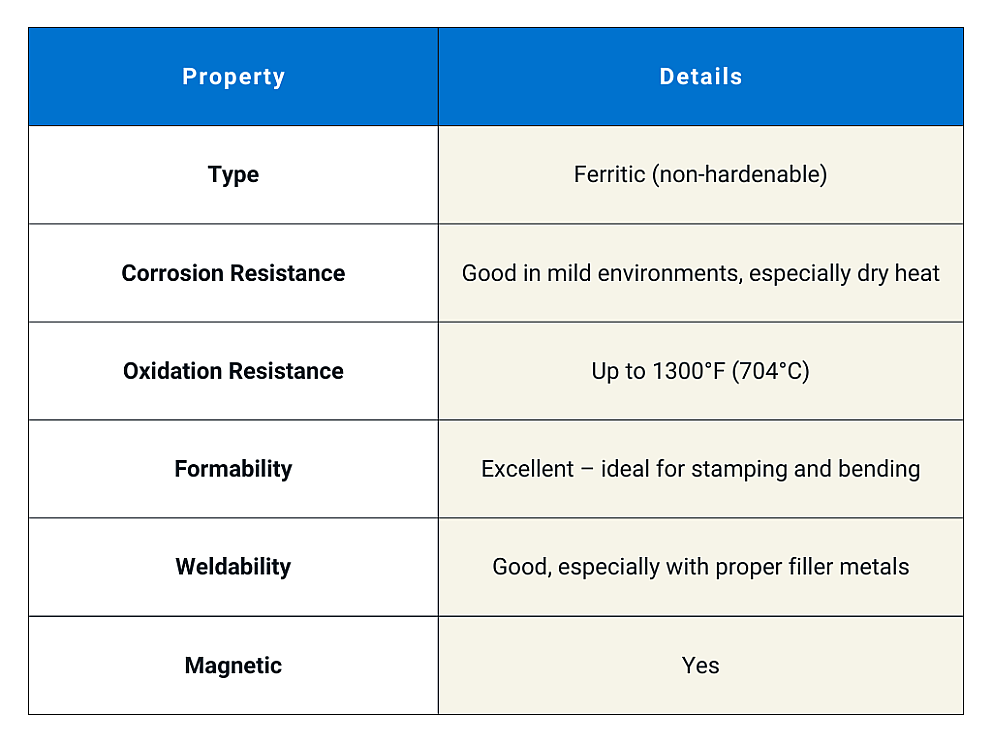

Key Properties of 409 Stainless Steel

Because of its leaner composition, 409 stainless is more affordable than austenitic grades like 304, making it ideal for high-volume or cost-sensitive applications where maximum corrosion resistance isn’t necessary.

Working With 409: Forming, Welding, and Machining Best Practices

409 stainless is well-regarded for its workability, but here are a few key considerations for fabrication teams:

Forming

409 is easily formed using standard bending and stamping techniques. Cold working increases strength slightly but won’t significantly affect corrosion resistance. Its low carbon content also reduces the risk of cracking during forming.

Welding

409 stainless is readily weldable by most conventional methods, including TIG and MIG. However, post-weld annealing is sometimes recommended to restore corrosion resistance. If filler material is needed, 409 or 430-grade filler rods can be used.

Machining

Though not as free-machining as some stainless grades, 409 performs adequately when proper speeds and feeds are used. Lubrication during cutting helps maintain tool life and surface finish.

Why Choose Mill Steel for 409 Stainless?

We don’t just stock material – we deliver reliability, consistency, and service. When sourcing 409 stainless steel from Mill Steel, you get:

- Slit-to-width coil and cut-to-length options to meet your exact specs

- National distribution from strategically located facilities

- High-quality processing that protects material integrity

- Short lead times and competitive pricing

- Dedicated account support from a responsive team

We’re committed to helping our customers meet production goals and cost targets without sacrificing quality. That’s why leading OEMs and fabricators trust Mill Steel as their stainless partner.

Contact us today or explore our stainless steel product offerings to get started.