Stainless Steel’s Melting Point: A Key Consideration for Manufacturers

When selecting materials for manufacturing, knowing the precise performance characteristics of your metals is essential. One key property that often comes into play, especially in high-heat applications, is the melting point of stainless steel.

Whether you're fabricating components for industrial ovens, designing structural elements, or sourcing material for heavy-duty equipment, understanding how stainless steel behaves under heat can inform smarter purchasing decisions and better long-term performance.

What Is the Melting Point of Stainless Steel?

The melting point of stainless steel typically ranges from 2,500°F to 2,800°F (1,370°C to 1,540°C), depending on the specific grade and chemical composition. Stainless steel is not a single material, it’s an alloy family that includes multiple grades, each formulated for different environments and applications.

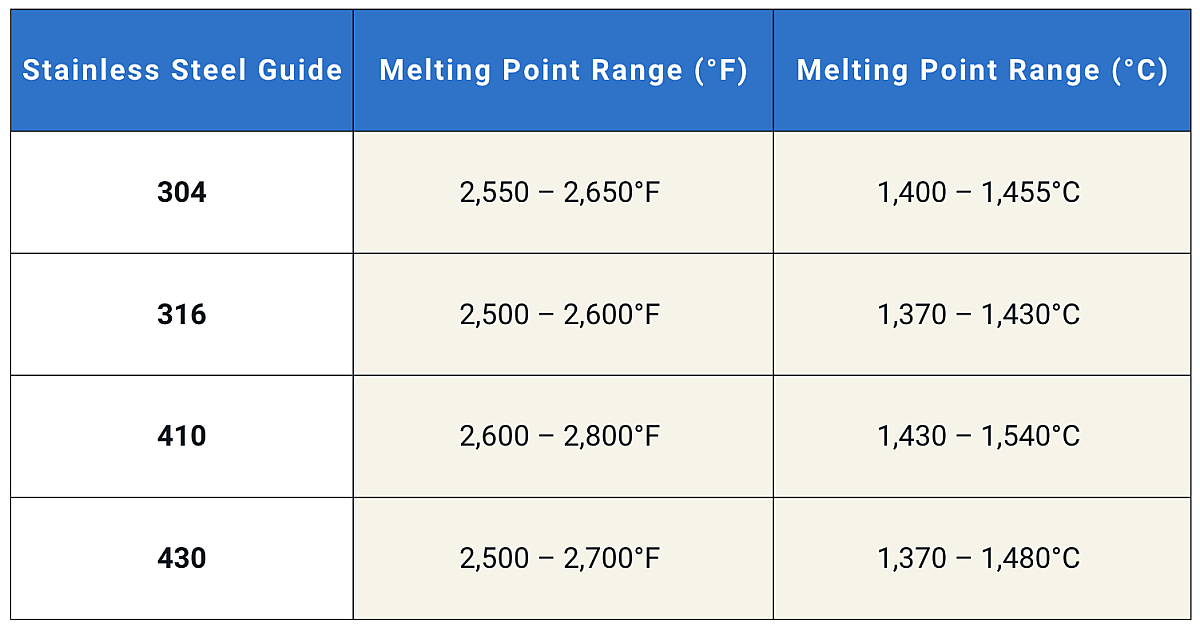

Here’s a breakdown of some common stainless steel grades and their approximate melting ranges:

Why the Melting Point Matters

In metal fabrication, high temperatures are often part of the processing – whether it's welding, cutting, or forming. Knowing your material’s melting point helps determine suitability for specific environments, especially in:

- Heat exchangers

- Industrial ovens and furnaces

- Automotive exhaust systems

- Chemical processing equipment

- Food-grade cooking surfaces

Choosing the right grade of stainless steel with the appropriate thermal properties ensures durability, safety, and performance across a wide range of operating conditions.

What Influences Stainless Steel's Melting Point?

The melting point of a stainless steel alloy is primarily influenced by its chromium and nickel content, as well as the presence of other alloying elements like molybdenum, carbon, and manganese. For example:

- Austenitic stainless steels (like 304 and 316) have lower melting points but higher corrosion resistance.

- Martensitic stainless steels (like 410) tend to have higher melting points but are more brittle.

- Ferritic stainless steels (like 430) offer good thermal conductivity with moderate melting ranges.

Sourcing Stainless Steel from a Trusted Partner

At Mill Steel Company, we supply a wide range of stainless steel grades suited for demanding industrial environments. Our team can help you select the optimal material based on your project’s thermal, mechanical, and corrosion-resistance requirements.

With nationwide distribution, precision processing, and industry expertise, we’re more than a supplier – we’re a strategic partner to your success.

Contact us today to talk with a product expert or explore our offerings online.