Ferrous vs. Non-Ferrous Metals: What's the Difference and Why It Matters

When you're sourcing materials for manufacturing, construction, or fabrication, understanding the key differences between ferrous and non-ferrous metals can make a major impact on your project's success. Knowing the properties and advantages of each metal type helps ensure performance, longevity, and value.

In this guide, we'll break down the basics of ferrous vs. non-ferrous metals, how to identify them, and which applications they best serve—especially in the steel and aluminum markets.

What Are Ferrous Metals?

Ferrous metals contain iron, making them magnetic and generally stronger and more durable than their non-ferrous counterparts. Common examples include:

- Carbon Steel

- Stainless Steel

- Cast Iron

- Wrought Iron

Due to their strength, ferrous metals are widely used in:

- Structural steel framing

- Automotive components

- Machinery and industrial tools

- Construction infrastructure

At Mill Steel Company, we offer a variety of carbon steel and stainless steel products that meet the demands of high-load, high-performance applications.

What Are Non-Ferrous Metals?

Non-ferrous metals do not contain iron, which means they are non-magnetic, more corrosion-resistant, and often lighter in weight. These properties make them ideal for environments where moisture, chemicals, or weight are critical factors.

Examples of non-ferrous metals include:

- Aluminum

- Copper

- Zinc

- Brass

- Nickel

At Mill Steel, we specialize in aluminum coils and sheet, which are ideal for roofing, siding, transportation, and energy markets thanks to their formability, resistance to rust, and lightweight nature. Learn more about our aluminum offerings here.

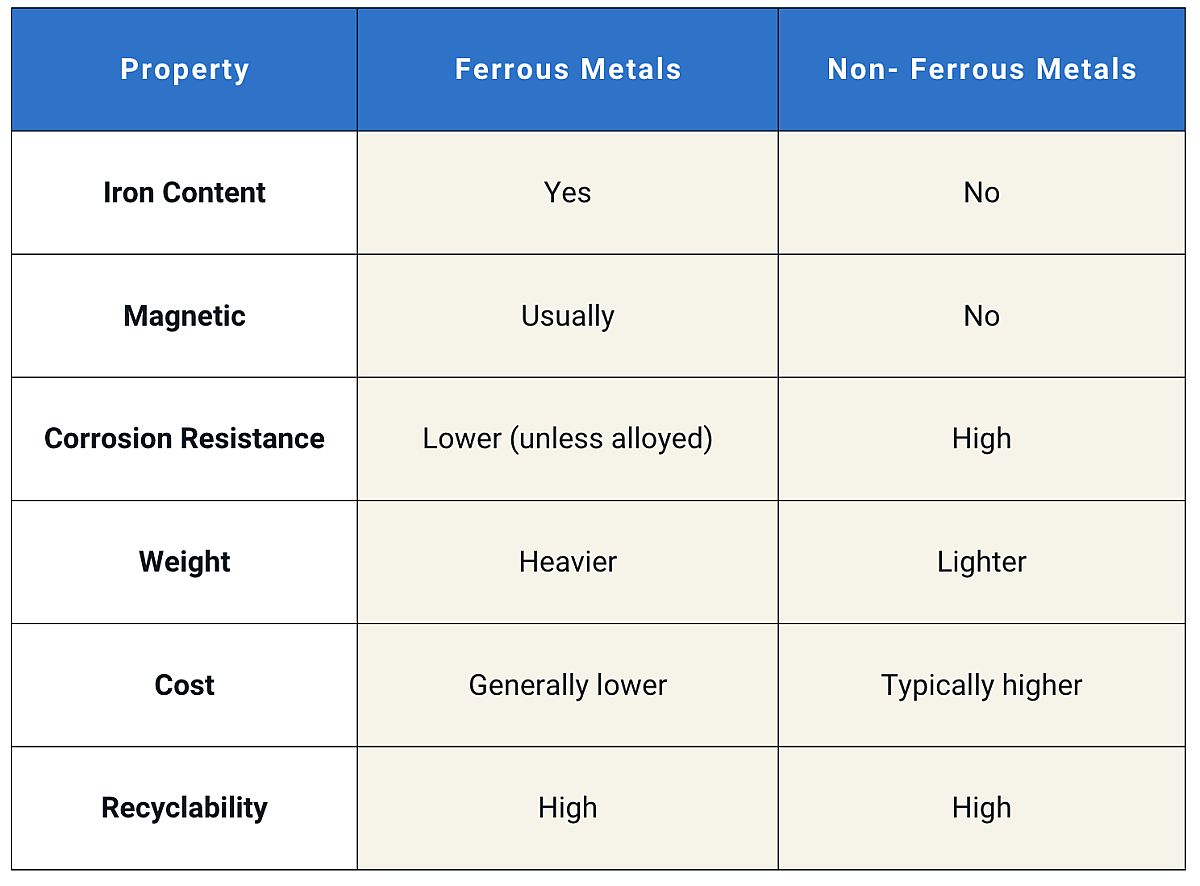

Key Differences: Ferrous vs. Non-Ferrous Metals

How to Choose the Right Metal for Your Application

When selecting between ferrous and non-ferrous metals, consider:

- Environment: Coastal or chemical-rich areas may demand non-ferrous options like aluminum.

- Strength Needs: Heavy machinery or high-impact construction often require ferrous metals.

- Weight Restrictions: Lightweight aluminum is preferred for transportation or elevated structures.

- Budget: Ferrous metals are generally more cost-effective for large structural applications.

If you're unsure what material best suits your needs, our knowledgeable sales team and metallurgical engineers are here to help. Contact us today to for expert material guidance.

Sustainability and Recycling

Both ferrous and non-ferrous metals are highly recyclable, making them excellent choices for environmentally responsible manufacturing and construction. In fact, the steel industry is one of the most recycled industries in the world. Learn more from the World Steel Association.

Similarly, aluminum recycling uses 95% less energy than producing new material. You can find more statistics on aluminum production and recyclability from The Aluminum Association.

At Mill Steel, we support a circular economy by sourcing and supplying high-quality recyclable metals for all industries.

The Bottom Line

Understanding the distinction between ferrous and non-ferrous metals is fundamental for any buyer in the metals market. Ferrous metals offer strength and durability at a lower cost, while non-ferrous metals provide superior corrosion resistance and lightweight advantages. At Mill Steel Company, we supply both – along with the service, processing, and logistics expertise to help your business succeed.

👉 Request a quote from our team

👉 Shop our online store for your metal needs