How Carbon Content Impacts Steel Strength and Performance

Steel is one of the most versatile materials in the world, used in everything from infrastructure and automotive to appliances and agriculture. But what gives steel its wide-ranging performance characteristics? A major factor is carbon content.

At Mill Steel Company, we help our customers select the right steel grade for their application. Understanding how carbon content affects steel’s strength, ductility, and machinability is essential to making the best choice.

What Is Carbon Steel?

Carbon steel is an alloy made primarily of iron and carbon. While other elements may be present in small amounts, carbon is the key influencer of the steel’s mechanical properties. Based on its carbon content, steel is typically categorized into three main types:

- Low Carbon Steel (up to 0.30% carbon)

- Medium Carbon Steel (0.30% – 0.60% carbon)

- High Carbon Steel (0.60% – 1.5% carbon)

Each type offers distinct performance traits that align with specific industry needs.

Low Carbon Steel: Malleable and Easy to Work With

Also known as mild steel, low carbon steel is the most commonly used variety. With its low carbon content, this steel is:

- Highly ductile and formable

- Easier to weld and machine

- More cost-effective for high-volume production

Because of its softness and ease of fabrication, low carbon steel is ideal for products like automotive panels, structural beams, and general-purpose tubing.

Medium Carbon Steel: A Balance of Strength and Toughness

Medium carbon steel strikes a middle ground between strength and flexibility. With more carbon than mild steel, it offers:

- Higher tensile strength

- Improved wear resistance

- Moderate machinability and weldability

This steel is commonly used in applications that require durability, such as rail components, gears, axles, and heavy-duty machinery parts.

High Carbon Steel: Maximum Hardness, Minimal Flexibility

High carbon steel delivers exceptional strength and wear resistance. However, the tradeoff is reduced ductility and more challenging fabrication. Key characteristics include:

- Extreme hardness and strength

- High resistance to abrasion

- Lower weldability and machinability

This type of steel is well-suited for cutting tools, blades, springs, and high-strength wires—where rigidity and performance under stress are critical.

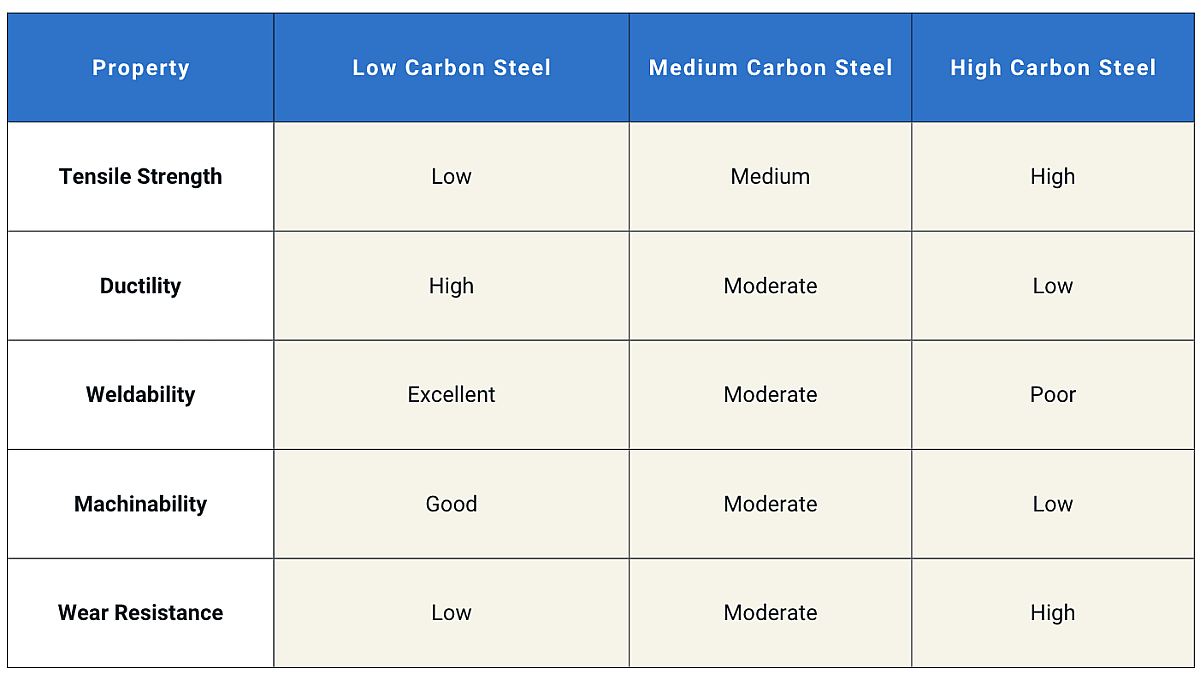

How Carbon Content Affects Steel Performance

Carbon content acts as a performance dial. Lower carbon means more flexibility and ease of forming; higher carbon brings hardness and strength, but at the cost of workability. Understanding this relationship is crucial in selecting the right grade for your project.

Choosing the Right Carbon Steel for Your Application

At Mill Steel, we offer a broad range of carbon steel grades and finishes tailored to your needs. Whether you’re manufacturing parts that require high formability or components that must endure extreme stress, we have a vast inventory selection and can supply the material you need.

We also provide a variety of processing services to support just-in-time delivery and reduce waste on your production floor.

Partner with a Steel Supplier Who Understands Performance

Backed by decades of industry experience and a commitment to exceptional service, Mill Steel is more than a supplier, we're your strategic partner. Contact us today to speak with one of our product experts or to request a quote.