Hot-Rolled vs. Cold-Rolled Steel: What’s the Difference and When to Use Each

When it comes to sourcing the right material for your next project, understanding the difference between hot-rolled and cold-rolled steel is key. While both materials are fundamental in the steel industry, they offer unique benefits depending on how they are processed and how you plan to use them.

At Mill Steel Company, we’re proud to be a trusted supplier of high-quality carbon flat-rolled steel products. Whether you're in construction, manufacturing, agriculture, or transportation, we’re here to help you make informed decisions that drive performance and value.

Here’s a closer look at how these steel types differ, how they’re made, and how to determine the best option for your specific steel applications.

Understanding the Rolling Process

Before diving into the differences, it helps to understand what “rolling” refers to. Rolling is a metalworking process where steel is passed through one or more pairs of rollers to reduce thickness and ensure uniformity. The temperature at which this happens — either above or below the recrystallization point — determines whether the steel is classified as hot-rolled or cold-rolled.

- Hot-Rolling: Performed at high temperatures (typically above 1,700°F), which is above the recrystallization point of steel.

- Cold-Rolling: Performed at or near room temperature after the steel has already been hot-rolled.

This temperature difference results in a number of mechanical and visual distinctions, impacting the steel's strength, surface quality, and dimensional precision.

What Is Hot-Rolled Steel?

Hot-rolled steel is one of the most commonly used carbon steel types in construction and manufacturing. It’s rolled at high temperatures, which keeps the material soft and workable. Once formed, it cools at room temperature, which can lead to minor warping or variations in size, but this isn’t usually an issue for structural-grade applications.

Advantages of Hot-Rolled Steel:

- Lower cost: Ideal for high-volume projects and large-scale production.

- Excellent workability: Easy to cut, weld, and form.

- Quick production time: Faster and more efficient to manufacture.

Limitations:

- Rougher surface finish: Not ideal for exposed parts without secondary processing.

- Less precise tolerances: Dimensional variations may occur during cooling.

Best used for:

- Building frames and columns

- Agricultural and heavy equipment

- Railroad tracks and transportation parts

- General fabrication projects

What Is Cold-Rolled Steel?

Cold-rolled steel is essentially hot-rolled steel that has been further processed. After the initial rolling and cooling, the steel is re-rolled at room temperature to improve its surface finish and refine its dimensions. This extra processing step results in a harder, stronger, and more aesthetically pleasing material.

Advantages of Cold-Rolled Steel:

- Smooth, clean appearance: Excellent for visible or painted components.

- Greater strength: Increased hardness and yield strength due to work hardening.

- Tight dimensional tolerances: Ideal for precision applications.

Limitations:

- Higher cost: Due to additional processing.

- Lower ductility: Can be more difficult to shape or form than hot-rolled steel.

Best used for:

- Automotive panels and underbody parts

- Appliances and electrical enclosures

- Furniture and storage units

- Metal doors, lockers, and shelving systems

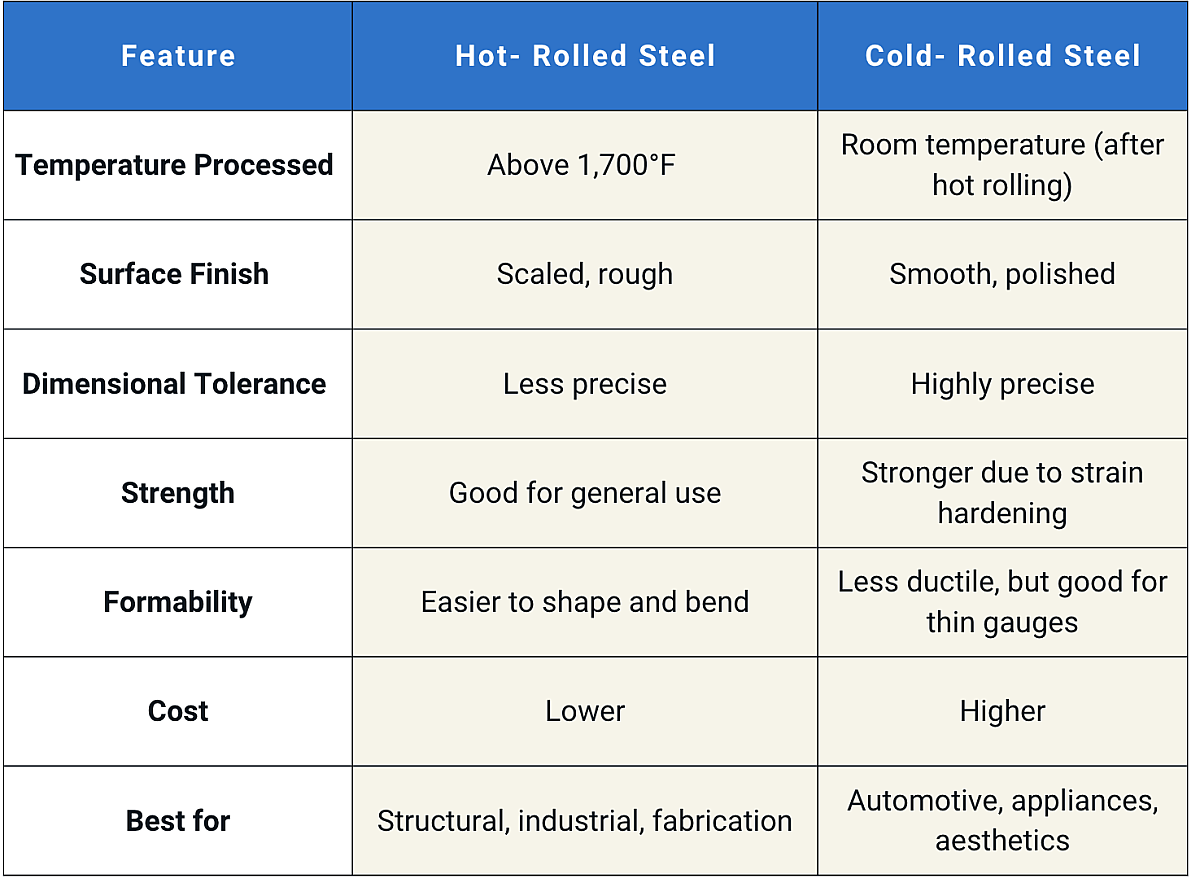

Hot-Rolled vs. Cold-Rolled Steel: Quick Comparison Guide

When choosing between hot-rolled vs. cold-rolled steel, think about your end use, required tolerances, and desired appearance.

Additional Tips for Selecting the Right Steel

- Need clean aesthetics or tight specs? Go with cold-rolled steel.

- Working on a budget or large structural project? Hot-rolled is likely your best option.

- Worried about corrosion? Consider galvanized steel, which starts as either hot-rolled or cold-rolled but receives a zinc coating for rust resistance.

- Concerned about machining? Cold-rolled steel often performs better in precision machining processes due to its consistent dimensions.

Mill Steel: Your Trusted Supply Chain Partner

At Mill Steel Company, we offer a full line of hot-rolled and cold-rolled carbon steel, as well as coated and painted products to meet a variety of steel applications. Our processing capabilities, national distribution network, and customer-first approach make us a trusted partner across industries—from construction and manufacturing to automotive and agriculture.

We work closely with our customers to recommend materials that meet their performance specs, budget, and lead times. Whether you need master coils, slit-to-width sizes, or custom cut-to-length material, we’re here to help streamline your supply chain and boost your bottom line.

Contact a product expert to discuss your project needs and request a quote or conveniently shop our products online.